Lintho tse bonahalang

| 'Mele | Aluminium(5050 5052 5056 5154) | (AL Mg 1%-1.5%, 2%-2.5% ,3%-3.5%,5%) | ||

| Qetella | E bentšitsoe | RAL 'Mala o Pentiloeng | ||

| Mandrel | Aluminium ● | Tšepe | Ts'epe e sa beng le mabali | |

| Qetella | E bentšitsoeng ● | Zinc e entsoeng | E bentšitsoe | |

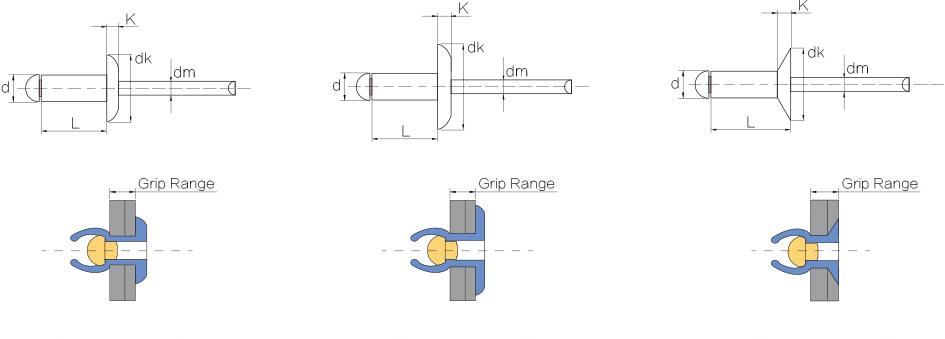

| Mofuta oa Hlooho | Dome, CSK, Flange e kholo | |||

Tlhaloso

| D1 NOMO. | BOKANG NO. & KHOLO EA LESOBA | ART.CODE | TS'OARA MAKA | L(MAX) | D NOMO. | K MAX. | P MIN. | SHEBA LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 3/32" 2.4 limilimithara | #41 2.5-2.6 | AA32 | 0.020-0.125 | 0.5-3.2 | 0.250 | 6.4 | 0.188" 4.8 | 0.032" 0.81 | 1.00" 25.4 | 70 310N | 80 360 N |

| AA34 | 0.126-0.250 | 3.2-6.4 | 0.375 | 9.5 | |||||||

| AA36 | 0.251-0.375 | 6.4-9.5 | 0.500 | 12.7 | |||||||

| 1/8" 3.2 limilimithara | #30 3.3-3.4 | AA41 | 0.020-0.062 | 0.5-1.6 | 0.212 | 5.4 | 0.250" 6.4 | 0.040" 1.02 | 1.06" 27 | 120 530 N | 150 670 N |

| AA42 | 0.063-0.125 | 1.6-3.2 | 0.275 | 7.0 | |||||||

| AA43 | 0.126-0.187 | 3.2-4.8 | 0.337 | 8.6 | |||||||

| AA44 | 0.188-0.250 | 4.8-6.4 | 0.400 | 10.2 | |||||||

| AA45 | 0.251-0.312 | 6.4-7.9 | 0.462 | 11.7 | |||||||

| AA46 | 0.313-0.375 | 7.9-9.5 | 0.525 | 13.3 | |||||||

| AA48 | 0.376-0.500 | 9.5-12.7 | 0.650 | 16.5 | |||||||

| AA410 | 0.501-0.625 | 12.7-15.9 | 0.775 | 19.7 | |||||||

| 5/32" 4.0 limilimithara | #20 4.1-4.2 | AA52 | 0.020-0.125 | 0.5-3.2 | 0.300 | 7.6 | 0.312" 7.9 | 0.050" 1.27 | 1.06" 27 | 190 850 N | 230 1020 N |

| AA53 | 0.126-0.187 | 3.2-4.8 | 0.362 | 9.2 | |||||||

| AA54 | 0.188-0.250 | 4.8-6.4 | 0.425 | 10.8 | |||||||

| AA56 | 0.251-0.375 | 6.4-9.5 | 0.550 | 14.0 | |||||||

| AA58 | 0.376-0.500 | 9.5-12.7 | 0.675 | 17.1 | |||||||

| AA510 | 0.501-0.625 | 12.7-15.9 | 0.800 | 20.3 | |||||||

| AA516 | 0.876-1.000 | 22.2-25.4 | 1.175 | 29.8 | |||||||

| 3/16" 4.8mm | #11 4.9-5.0 | AA62 | 0.020-0.125 | 0.5-3.2 | 0.325 | 8.3 | 0.375" 9.5 | 0.060" 1.52 | 1.06" 27 | 260 1160 N | 320 1430 N |

| AA63 | 0.126-0.187 | 3.2-4.8 | 0.387 | 9.8 | |||||||

| AA64 | 0.188-0.250 | 4.8-6.4 | 0.450 | 11.4 | |||||||

| AA66 | 0.251-0.375 | 6.4-9.5 | 0.575 | 14.6 | |||||||

| AA68 | 0.376-0.500 | 9.5-12.7 | 0.700 | 17.8 | |||||||

| AA610 | 0.501-0.625 | 12.7-15.9 | 0.825 | 21.0 | |||||||

| AA612 | 0.626-.0750 | 15.9-19.1 | 0.950 | 24.1 | |||||||

| AA614 | 0.751-0.875 | 19.1-22.2 | 1.075 | 27.3 | |||||||

| AA616 | 0.875-1.000 | 22.2-25.4 | 1.200 | 30.5 | |||||||

| AA618 | 1.001-1.125 | 25.4-28.6 | 1.325 | 33.7 | |||||||

| AA620 | 1.126-1.250 | 28.6-31.8 | 1.450 | 36.8 | |||||||

| 1/4" 6.4 limilimithara | F 6.5-6.6 | AA82 | 0.020-0.125 | 0.5-3.2 | 0.375 | 9.5 | 0.500" 12.7 | 0.080" 2.03 | 1.25" 32 | 460 2050 N | 560 2500N |

| AA84 | 0.126-0.250 | 3.2-6.4 | 0.500 | 12.7 | |||||||

| AA86 | 0.251-0.375 | 6.4-9.5 | 0.625 | 15.9 | |||||||

| AA88 | 0.376-0.500 | 9.5-12.7 | 0.750 | 19.1 | |||||||

| AA810 | 0.501-0.625 | 12.7-15.9 | 0.875 | 22.2 | |||||||

| AA812 | 0.626-0.750 | 15.9-19.1 | 1.000 | 25.4 | |||||||

| AA814 | 0.751-0.875 | 19.1-22.2 | 1.125 | 28.6 | |||||||

| AA816 | 0.876-1.000 | 22.2-25.4 | 1.250 | 31.8 | |||||||

| AA818 | 1.001-1.125 | 25.4-28.6 | 1.375 | 34.9 | |||||||

Kopo

Aluminium ea rona e felletseng ea open end rivet e sebelisa lithapo tsa boleng bo holimo tsa aluminium alloy.Ka mor'a riveting, E ke ke ea hlola e rusa.Ha ho bapisoa le li-rivets tse tloaelehileng, matla a rivet a tlase, ka hona a loketse bakeng sa ho hokela lintho tse bonolo. Li-rivets tsa pop tsa aluminium li ka aroloa ka rivet ea hlooho ea dome, li-rivets tsa li-countersunk le li-rivet tse kholo tsa hlooho. alu mg 2% 2.5% 3.5% le 5% (5052 5154 5056).

Li-rivets tsa mofuta o bulehileng oa Fixpal li na le melemo ea ts'ebetso e bonolo, riveting e ntle haholo, ponahalo e ntle, thepa e phahameng ea 'mele.Khetho e phethahetseng ea li-riveting tse nang le mahlakoreng a le mong.Aluminium pop rivets e ka sebelisoa haholo likoloing tse sa tšoaneng, likepe, tlhahiso ea mechine, lisebelisoa tsa elektronike, lisebelisoa, mechine ea lijo, thepa ea bongaka, kaho, mokhabiso le libaka tse ling tse tiisang.

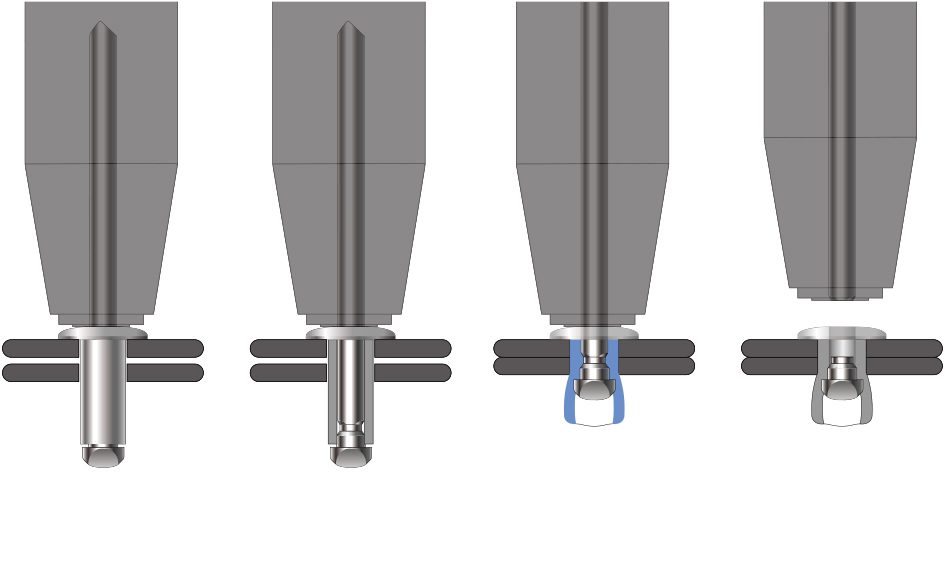

Mathata le mabaka ha u sebelisa rivet e foufetseng:

1. Burrs: Ka mor'a ho riveting, mandrel e robehileng e nang le li-burrs e feta likoti tsa rivet;kapa masoba a riveting a hlahella ka ntle ho etsa spatula burr.

Sesosa sa li-burrs: bophara ba mandrel bo nyane;thepa ea rivet e bonolo;bophara ba lesoba la ho cheka la workpiece e kholo haholo;litlhaloso tsa molomo oa sethunya sa rivet li kholo haholo;

2. Hlooho ea lenala ea oa: Ka mor'a hore rivet e huloe, hlooho ea rivet ea mantlha e ke ke ea phutheloa 'me ea oa ho tloha rivet.

Mabaka a ho oela hlooho ea rivet ea mantlha ke: bophara ba sekoahelo sa sepekere se seholo haholo;rivet e khuts'oane, 'me botenya ba rivet ha bo lumellane.

3. ho phunyeha ha rivet: Ka mor'a ho riveting, rivet e phunyeletsoa kapa e phatlohile ka ho feletseng.

Mabaka a ho phunyeha ha rivet ke: boima bo feteletseng ka mor'a ho tsuba annealing kapa phekolo e se nang mocheso, katiba ea lipekere e kholo haholo.