Lintho tse bonahalang

| Lintho tse bonahalang | Aluminium | Tšepe | Ts'epe e sa beng le mabali |

| Qetella | E bentšitsoe | Zine Plated | E bentšitsoe |

Tlhaloso

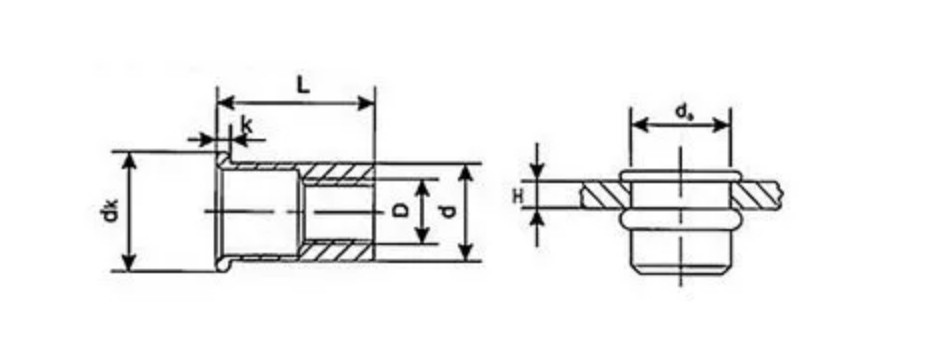

| KHOUTU | Boholo d | Grap Range e | Bolelele h | D. +0,15 +0.05 | D -0.03 -0.2 | dk +0,30 -0.30 | K +0.2 -0.20 | L +0,30 -0.30 | |

| SM3 | SM3R | M3 | 0.5–2.0 | 5.0 | 5 | 5 | 5.5 | 0.4 | 8.5 |

| SM4 | SM4R | M4 | 0.5–2.0 | 5.5 | 6 | 6 | 6.75 | 0.5 | 10.0 |

| SM5 | SM5R | M5 | 0.5 ho isa ho 2.5 | 6.0 | 7 | 7 | 8.0 | 0.6 | 12.0 |

| SM6 | SM6R | M6 | 0.5–3.0 | 9.0 | 9 | 9 | 10.0 | 0.6 | 14.5 |

| SM8 | SM8R | M8 | 0.5 ho isa ho 3.5 | 10.0 | 11 | 11 | 12.5 | 0.6 | 16.5 |

| SM10 | SM10R | M10 | 0.5 ho isa ho 3.5 | 12.0 | 13 | 13 | 14.5 | 0.85 | 19 |

| SM12 | SM12R | M12 | 0.5 ho isa ho 3.5 | 14.5 | 15 | 15 | 16.5 | 0.85 | 22.5 |

Kopo

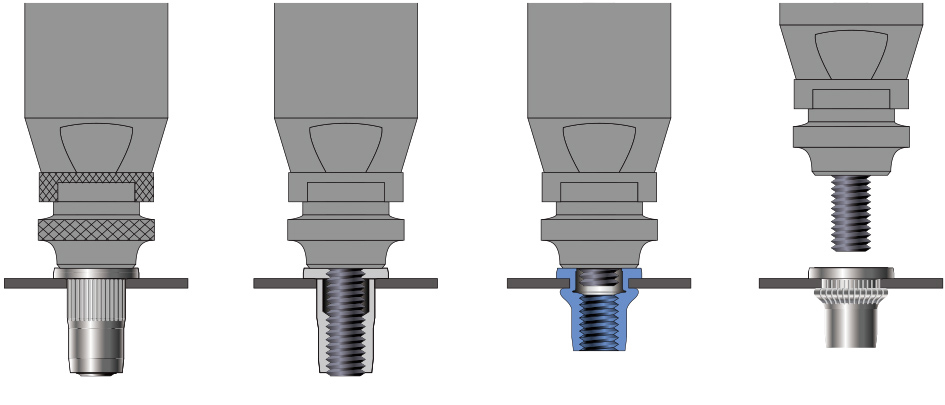

Rivet nut, eo hape e tsejoang e le nate ea ho kenya, e sebelisoa libakeng tse tiisang mefuta e fapaneng ea lipoleiti tsa tšepe, liphaephe le liindasteri tse ling tsa tlhahiso.E le ho rarolla lipoleiti tse tšesaane tsa tšepe le linate tse tšesaane tsa welding, substrate e bonolo ho tjheseletsa le ho senyeha, 'me khoele e ka hare e etsoa.Ha e hloke ho hlasela likhoele tse ka hare, ha ho na linate tse chesellang, matla a phahameng a rivet, le tšebeliso e bonolo.Nate ea rivet e ka rarolla khetla ea moea ka nepo, mme e khona ho fokotsa mathata a joalo ka welding ea nnete.

Litlhaloso tsa ho kenya linate tsa rivet li hlile li arotsoe ka bongata, joalo ka litekanyetso tsa linate tsa rivet tse sebelisoang ka mefuta e sa tšoaneng kapa boholo bo fapaneng ba lik'habote li fapane.Karolo e 'ngoe ea thepa ea nate ea rivet e entsoe ka tšepe ea carbon,' me sebōpeho sa eona se chitja.Litlhaloso tsa likhoele tsa bona li lipakeng tsa M2 le M10.Boholo ba bophara bo ka ntle ba tšiea ena ea linate tse riveting ke 6.3 mm -17.35 pakeng tsa limilimithara.Boholo le botenya ba tšiea ea khoele ea riveting e lokela ho thehoa holim'a lintho tse lokelang ho kenngoa.

Tšebeliso ea linate tsa rivet ho air conditioning:

1. Nate ea rivet e ka rarolla ka katleho khetla ea mocheso oa moea, ea theha bothata ba "metsi a mosehla" ka mor'a nako e telele, 'me e ka fokotsa ka katleho mathata a kang ho tjheseletsa ha sebele.

2. Rivet nut e nkile sebaka sa terata ea tlhaselo e ka fokotsang thepa ka 20% le ho boloka matla.

3. Ho rarolla li-screws tsa ho itšireletsa ha li na matla, 'me ho tšepahala ho ka fokotseha.E ka fokotsa lerata le hlahisoang ke ho lokoloha ka lebaka la khokahano, e ka tšeptjoang, e matla le e bonolo haholoanyane.

4. Ntlafatsa katleho ea tlhahiso, fokotsa palo ea basebetsi, le ho fokotsa litšenyehelo tsa basebetsi.(Hobane linate tsa rivet li sebelisa mokhoa oa ho riveting ea crusher ea punch, mokhoa o le mong oa welding o phethoa ka nako e le 'ngoe, e seng feela e sebetsang hantle, empa hape e fokotsa palo ea tšebeliso.

5. Fokotsa mobu oa fektheri.

-

Aluminium e nang le Aluminium Mandrel Open Type Blind...

-

Stainless Steel le Stainless Steel Mandrel Se...

-

Tšepe e nang le Steel Mandrel e Tiisitsoeng ea Mofuta oa Rivet

-

Stainless Steel Uni Grip Rivet Matla a Phahameng ...

-

Stainless Steel with Stainless Steel Mandrel Mu...

-

Tšepe e nang le Steel Mandrel Multi Grip Sefofu ...